Artificial reefs

|

Contents

Introduction

An artificial reef (AR) can be defined as any solid man-made structure which has been submerged in the natural environment (Bohnsack, 1989[1]). They may be purposely placed to alter local hydrodynamics (coastal defense ARs) or this effect may be incidental (ship wrecks, offshore windmills, oil rigs etc.). Regardless of their construction or purpose, artificial reefs generally involve the introduction of a hard substrate to a soft bottom environment, altering both the abiotic as the biotic properties of the environment. Coastal defense artificial reefs are therefore often constructed as multipurpose structures, i.e. besides the main function to defend the coast from erosion they also maximise secondary objectives such as to improve spot surfability, to stabilize nourishment material and to create marine parks of increased biodiversity. Since different aims, materials and configurations as well as site dependent factors are to be considered, design criteria for these structures are not easily defined a priori.

Materials

Stones

Stones are especially used for rubble mound structures whose hydraulic stability is verified through the formulae available in literature for low-crested structures (Burcharth et al., 2007 [2]). Un-corrected design of the structure by a wrong selection of stone size causes a low efficiency of the AR. Structure reshaping induced by wave breaking over the reef may occur and produce instability, with stones rolling down from the structure. Stones are relatively cheaper than other materials but can be more dangerous for surfing safety.

Geobags, geotextile sand containers and geotubes

Geotubes consist of sacks made by geotextile that are filled with sand or gravel. They are characterized by a length and diameter of 20 and 3 m respectively and are particularly recommended for deep bottoms (Matteotti et al., 2003[3]). Geotextile sand containers (GSCs) and geobags are very similar to geotubes, although their dimensions are smaller than that and thus are usually adopted at lower depths. The cost of a reef made of GSCs is usually greater than in case of other materials because of the difficult placement. GSCs and geobags are often employed as revetments or as seaward slopes of nearshore structures. Unfortunately, no exhaustive analyses regarding element stability are available the need to combine numerical and physical models with practice and experience in the field to establish the real stability of the GSC remains.

The Narrowneck reef is perhaps the most successful example of an ASR because it requires a modest maintenance degree, while a lot of benefits are obtained in terms of coastal defense and development of surfing sports. The required maintenance after the construction has been very low, consisting in the addition of only 50 GSCs in 6 years (Jackson et al, 2007[4]). The main objectives of this ASR were to enlarge the beach and to improve the spot surfability. Therefore, this reef consists of two arms with a central channel in between to ensure slow rip currents (Jackson et al, 2002[5]). The ASR in Narrowneck is composed of 458 geotubes, placed at depths ranging between 1.5 (crest) to 10 meters water depth (low tide). The reef is 270 m long (cross shore direction) and 170 m wide (longshore direction), covering a total volume of 120,000 m3. The geotextile sand containers were filled with 100-300m3 of native sand in order to eliminate the contamination hazard in case of breaking (Jackson et al, 2002[5]). The Narrowneck reef contributes significantly to the stabilisation of the nourished beach and induced the formation of a salient which is approximately 50 m wide cross-shore. With regards to the second goal, surfable waves are reproduced on average for 184 days/year, with spilling or plunging breakers in case of weak storms and typically plunging breakers for intense storms (Jackson et al, 2007[4]). Finally, the GSC surface was found to be intensely colonized by marine flora (Jackson et al, 2007[4]).

Reef units

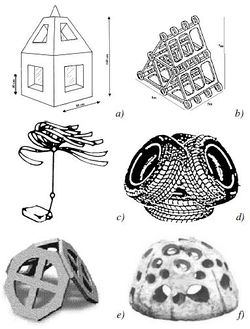

Reef units of different shapes and constructive characteristics can be used to produce ARs. Their macro-roughness induces the dumping of the incident wave agitation above the reef, creating local turbulence and vortices. Usually they are made by steel, reinforced or pre-stressed concrete, fibreglass or a variety of composite materials. These units are produced individually on shore and transported to the staging area. Here they could be combined in a variety of configurations thus allowing adjustment to local conditions and needs. Most of the units are designed to provide nursery areas for fish, to permit a good water recirculation, promote current deflections and marine colonization (O’Leary, 2001[6]). Some examples are shown in Figure 1.

Figure 1.e shows the so-called tecnoreef modules. Constructed from concrete-based natural products, they pose little impact on the ecosystem. Each module consists of reinforced octagonal plates, which are characterized by holes (usually four) having a quarter of a circle shape. The modules are assembled together to create a sort of pyramid that usually consists of three octagonal plates, the so called “base system”. The structure basis is made larger than the crest thus ensuring the resistance and stability to cross-shore currents and drag forces. They globally reduce cross-shore currents due to friction and turbulence The consequent deposition of transported sediments within and around the pyramids is increased by the differently inclined facets on the external and internal surfaces of the modules. These irregularities facilitate localized microcurrents and create continuous circular currents (spheres of water) which release their energy upwards within each element. The constant circulation and exchange of water allows the influx of nutrients and permanent occupation by flora and fauna.

Equally note-worthy are the reef ball elements shown in Figure 1.f. These have an hemispherical shape (Harris, 1995[7]) and are typically 1-2 m high and 2 m wide. A reef ball is made by polyester with glass reinforcement and is thus very resistant to corrosion. The reef ball contains a buoy that allows it to float during construction phase and that is deflated when the element is definitively placed. They are characterised by high porosity (40-50%), roughness and many cavities or holes which have a double action. First off, the roughness and holes increase the structure complexity which assures a quick colonisations by marine species and aquatic plants (Pilarczyk, 2003[8]). Secondly, these structures are specifically designed to generate turbulence, vortices and vertical jets which dissipates wave energy. Under storm attacks, the geometry of reef balls reduces its stability whereas its porosity, through the reduction of lifting forces, causes a beneficial compensating effect.

The Grand Cayman reef (Cayman Islands) was one of the first examples of an Reef ball artificial reef. Between 2002 and 2005, approximately 230 Reef Ball units, ranging in size between 9 to 11 m width and 1.3 to 1.6 m height, were placed in 5 rows on the predominantly rocky bottom (Harris, 2009[9]). A gap is placed in front of the shallowest and widest part of the adjacent natural rock reef. The purpose of the reef was to restore the beach in front of the “Marriott beach resort” that disappeared in 2002 due to severe erosion during storm surges. The monitoring activities during the years 2002-2007 (Arnouil, 2008[10]) documented an average shoreline accretion of 18 m just 3 months after the reef installation and an almost complete beach restoration (peak width of 30 m) in 2006. The profile of the beach showed some relevant changes. In 2002, before the construction of the reef, the elevation of the highest point was below mean sea level. After the reef construction there was a significant increase in elevation, from +1.0 m to +1.8 m along the shore (3 months later). Between 2003 and 2007 a berm formation was observed in correspondence of the reef. The berm height (from +0.7 m to +1.0 m) and width (from 7 m to 10 m) are increased significantly till the summer of 2007 and then appeared stable same till now (Arnouil, 2008[10]).

Geometry

Layout

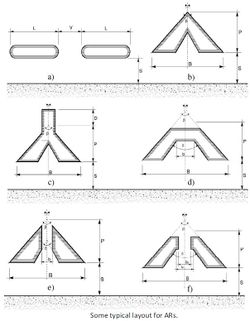

There are many schemes adopted for ARs, especially for those made by geotextile, depending on their principal function. After defining the objectives to be achieved, an appropriate geometry can be selected. Here, the case of submerged structures that are used to defend the coast from erosion are primarily considered. The layout in Figure 2.a represents the traditional configuration of gap separated rubble mound barriers parallel to the littoral zone. The waves that break over the reef induce an inshore increase of sea level and a simultaneous decrease of wave height due to energy dissipation over the crest (Pilarczyk, 2003[8]). Figure 2.b - 2.f shows some sample layouts for artificial reefs and artificial surfing reefs (ASRs). Overall, the structure is composed by two convergent wedges and a focus where the waves break (Ranasinghe et al., 2006[11]), defining a-frame waves, i.e waves that break in a central point while breakpoint evolves in symmetrical way from the case of submerged structures that are used to defend the coast from erosion. The geometries in figures 2.d and 2.f show a large front of the structure parallel to the shore and thus are characterized by an intermediate behaviour between a simple AR and an ASR. Many modifications exist where a central channel (also referred to as a rip channel or paddling channel) is introduced to the scheme (Van Ettinger, 2005[12]). Fig. 2.f represents such an ASR with a central gap. The focus gap can be at the same depth of the seabed or raised from it. The rip channel reduces the intensity of rip currents and thus increase safety of surfers.

Cross-section

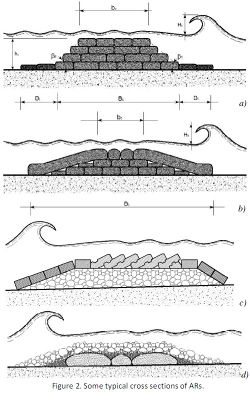

The cross-section of ARs varies according to the used materials and the main function of the structure. Figure 3.a shows the cross section of a submerged barrier made of GSCs. The crest width of such a reef is much greater than that of traditional low crested structures and rubble mound breakwaters. The crest width must in fact be sufficiently large to dissipate wave energy (Pilarczyk, 2003[8]). Moreover, both seaward and landward slopes are steeper than in traditional breakwaters, reducing the volumes of material together with construction costs. In the body of the barrier, GSCs are longitudinally disposed whereas on the landward and seaward slopes GSCs are transversely disposed (Koerner et al., 2006[13]). This reduces the number of gaps which are exposed to breaking waves, increasing AR stability (Recio et al., 2009[14]). In figure 3.b, the body of the reef is composed by differently sized GSCs in order to fill all the gaps between the GSCs (Recio et al., 2009[14]), while the seaward and landward slopes are covered by geotubes. Clearly, for geotubes stability the angle at seabed must be lower than in the previous scheme. Figure 3.c shows an Aquareef that is composed by an internal core made of rubble stones and one upper layer of special blocks that induce localized turbulence, dissipating incident wave energy. This scheme is the most common on Japanese coasts (Pilarczyk, 2003[8]). The Iburi reef in Hokkaido is an example of this peculiar reef design. In Figure 3.d the core of the reef is made of geotubes characterized by different dimensions while armour and filter layers are composed by stones (Pilarczyk, 2003[15]). This ASR profile is characterized by a submerged crest over which the waves peel (Figure 3). A linear or convex profile for wedges can be adopted (Van Ettinger, 2005[12]). Convex is better can compensate the change of the breaker intensity but it is more difficult to be constructed while the easier constructed linear profile is creates the phenomenon of “wave pinching” i.e. a reduction of the pipe under plunging waves (Mead, 2003[16]). At the back of the ASR, wedges can be cut or uncut to modulate the velocity of rip and longshore currents. If a cut profile for wedges is adopted, the velocity of rip currents is generally lower than with the un-cut profile (Van Ettinger, 2005 [12]).

Dimensions

The size of the barrier depends on its use. If we consider a barrier for coastal protection, as in Figure 2.a, the parameters to be estimated are the crest and gap width (Pilarczyk, 2003[8]). For the first it is important to define the desired transmitted wave height or, in other words, the transmission coefficient. For the second, it is important to estimate the rip current velocities in order to establish an appropriate gap width. Moreover, it has to be considered that an increase of the rip channel may decrease the speed of rip currents but, at the same time, it may increase the transmission coefficient Kt (Van der Meer et al., 2005[17]). Another critical parameter is crest submergence, since it has to cope with the desired value of Ktas well as account for safe conditions for swimmers and surfers within the tidal excursion of the construction site. The depth of the structure crest has to be related to the breaking wave height. The following method (CEM, 2001[18]) is provided for estimating the wave breaking height (Hb) and breaking depth (hb). This method is based on the deep water un-refracted wave height (H0’), the offshore wave length (L0) and the seabed slope (m). By defining the breaker height index as:

the wave breaking height is:

Deriving Hb from this equation, provided the breaker index wb is known and the waves are depth-limited, it can be written:

Hb can be estimated by the following formula:

where a and b depend on the seabed slope m as follows:

The appropriate crest width of the reef (B) can be derived considering: - the reef crest must be greater than the plunge distance which is the distance between plunge and break point, in order to assure that waves break over the crest. There is an empirical formula based on laboratory tests (Smith and Kraus, 1990[19]) that provide the plunging distance XP. - B is related to the transmission coefficient KT (Pilarczyk, 2003.a[8]) and therefore, fixing an appropriate value for KT, B is derivable from some formulae in literature.

with the following equation valid for 0.29 < Iribarren e Battjes parameter ξ < 3.46:

Wave transmission coefficient KT is typically in the range 0.3-0.7 for a cross-section of an Aquareef. Transmitted wave heights decrease with increasing relative wavelength and are affected by wave breaking, i.e. when 3Rc/H1 is relatively small, with Rc being the submergence, waves easily break on the reef and in this particular case KT is smaller than in the other cases (Hirose et al., 2002[20]). It is observed that wave energy dissipation (Hamaguchi et al., 1992[21]) is greater for the Aquareef unit type than for the rubble stones, though the values are similar when Rc/Hi < 1. Therefore KT can be determined by formulae valid for submerged rubble mound structures (Van der Meer et al., 2005 [17]), which include the crest width B to describe the behavior of KT when Rc=0. For example, the d’Angremond et al. formula (1996[22]) reads:

where, Hi is the incident wave height. In this formula, KT is limited between 0.075 and 0.8. This equation tends to overestimate KT when B/Hi >10 and therefore an attempt to improve the description of KT was done in recent studies (Van der Meer et al., 2005[17]). A suitable formula (Van der Meer et al., 2005[17]) for submerged structure having a large relative crest width (B/Hi >10) is:

Function

~INCOMPLETE~

See also

References

- ↑ Bohnsack, J.A., 1989. Are high densities of fishes at artificial reefs the result of habitat limitation or behavioral preference? Bulletin of Marine Science. 44, 631-645.

- ↑ Burcharth, H. F., Hawkins, S., Zanuttigh, B., and Lamberti, A., 2007. Environmental Design Guidelines for Low Crested Coastal Defence Structures, Elsevier.

- ↑ Matteotti G., Ruol P., 2003. L’impiego dei geosintetici nelle opere di ingegneria marittima e costiera, 2003 [1]

- ↑ 4.0 4.1 4.2 Jackson, L, Corbett, B., Tomlinson, R., McGrath, J., Stuart, G., 2007. Narrowneck Reef: Review of Seven Years of Monitoring. [2]

- ↑ 5.0 5.1 Jackson, L.A., Tomlinson R., McGrath, J., Turner, I., 2002. Monitoring of a multi functional submerged geotextile reef breakwater. Proceedings of the 28th International Conference on Coastal Engineering 7-12th July 2002 Cardiff, Wales.

- ↑ O’Leary, Hubbard T., O’Leary D. Artificial Reefs Feasibility Study, Coastal Resources Centre National University of Ireland Cork, 2001

- ↑ Harris, L.E., 1995. Engineering design of artificial reefs. Oceans '95, Marine Technology Society, Washington, D.C., Vol. 2, pp. 1139-1148.

- ↑ 8.0 8.1 8.2 8.3 8.4 8.5 Pilarczyk, K.W., 2003. Alternative systems for coastal protection: an overview. International Conference on Estuaries and Coasts November 9-11, 2003, Hangzhou, China.

- ↑ Harris, L.E., 2009. Artificial Reefs for Ecosystem Restoration and Coastal Erosion. Protection with Aquaculture and Recreational Amenities, Reef Journal. 1(1), pages 235-246.

- ↑ 10.0 10.1 Arnouil D.S., 2008. Shoreline Response for a Reef Ball Submerged Breakwater System Offshore of Grand Cayman Island. Thesis of Master of Science in Ocean Engineering, submitted to Florida Institute of Technology, Florida (2008). [3]

- ↑ Ranasinghe, R., Turner, I.L., 2006. Shoreline response to submerged structures: A review. Coastal Engineering. 53, 65– 79.

- ↑ 12.0 12.1 12.2 Van Ettinger, H.D., 2005. Artificial surf reef design. Thesis at Delft University of Technology, 2005. [4]

- ↑ Koerner, G.R., Koerner, R.M., 2006. Geotextile tube assessment using a hanging bag test. Geotextiles and Geomembranes. 24, 129–137

- ↑ 14.0 14.1 Recio, J., Oumeraci, H., 2009. Process based stability formulae for coastal structures made of geotextile sand containers. Coastal Engineering. 56, 632–658.

- ↑ Pilarczyk, K.W., 2003. Design of low-crested (submerged) structures – an overview. 6th International Conference on Coastal and Port Engineering in Developing Countries, Colombo, Sri Lanka.

- ↑ Mead, S., 2003. Surfing Science. Proceedings of the 3rd International Surfing Reef Symposium, Raglan, New Zealand, June 22-25, 2003.

- ↑ 17.0 17.1 17.2 17.3 Van der Meer, J. W., Briganti, R., Zanuttigh, B.,Wang, B., 2005. Wave transmission and reflection at low-crested structures: Design formulae, oblique wave attack and spectral change. Coastal Engineering. 52, 915–929.

- ↑ Coastal Engineering Manual, 2001. Department of Army, U.S. Army Corp of Engineers. [5]

- ↑ Smith, E. R., Kraus, N.C., 1991. Laboratory study of wave-breaking over bars and artificial reefs. Journal of Waterway, Port, Coastal and Ocean, 1991.

- ↑ Hirose, N., Watanuki, A., Saito, M., 2002. New Type Units for Artificial Reef Development of Eco-friendly Artificial Reefs and the Effectiveness Thereof. PIANC Congress, Sydney, see also 28th ICCE, Cardiff.

- ↑ Hamaguchi, N. Watanuki, A., Hasegawa, M., Noguchi, M., 1991. Development of submerged breakwaters for harmonized fisheries. Proceedings of The Japanese Society of Fisheries Engineering, 67-68.

- ↑ d’Angremond, K., van der Meer, J.W., de Jong, R.J., 1996. Wave Transmission at Low-Crested Structures. Coastal Engineering 1996, pp. 2418-2427.

Please note that others may also have edited the contents of this article.

|