Stability of rubble mound breakwaters and shore revetments

Extensive treatments on the stability of shore protection structures under the influence of waves and currents can be found in the Rock Manual [1], the Coastal Engineering Manual [2] and in textbooks such as the Introduction to bed, bank and shore protection (Schiereck, 1993) and Dikes and revetments (Pilarczyk, 1998).

This article provides a short introduction to the topic by summarising a few important notions, focusing on the example of rubble mound breakwaters and shore revetments.

Contents

- 1 Introduction

- 2 Design of shore protection structures

- 3 Failure modes

- 3.1 Hydraulic instability of the armor layer

- 3.2 Scour (erosion) at the toe of the construction

- 3.3 Erosion of the rear side (lee side) of a rubble mound breakwater

- 3.4 Erosion at the top of a rubble mound protection revetment

- 3.5 Washout of fine sediments from the core of the structure

- 3.6 Soil liquefaction under the structure

- 3.7 Slip surface failure within the core

- 3.8 Instability of the foreshore

- 4 Armor layer stability

- 5 Toe stability and bed/scour protection

- 6 Determination of the design conditions

- 7 Further reading

- 8 References

Introduction

Shore protection structures are generally built to protect shorelines from ongoing erosion or to shelter areas from strong wave and current action. Shore protection structures can be divided into coastal (protection) structures and river (protection) structures. Here, the focus is on coastal structures. Coastal structures are e.g. breakwaters, dikes, revetments, groynes, seawalls/quay walls. They can either be monolithic (such as seawalls, caisson breakwaters or crest elements directly cast from concrete) or made of individual layers which interact with each other (e.g. armor layers of rock and/or artificial armor units, block revetments; underlayers made of rock, clay or sand and a structure core made of sand or rubble). A special category of coastal structures are geosystems (e.g. sand-filled geocontainers and geotubes; these structures are dealt with in the article Sand-filled geosystems in coastal engineering) and gabions. Coastal structures can influence the shoreline morphology in several ways; this influence is described e.g. in the articles Seawalls and revetments, Human causes of coastal erosion and Detached breakwaters.

Whereas rock and sand structures are flexible to some extent, monolithic structures are often rigid. In this article we focus on rubble mound breakwaters (RMB). The main advantages of these structures, compared to monolithic structures, are: (1) flexibility - the potential to accommodate (small) changes in seabed/beach level; (2) potential to dissipate wave energy, thus reducing wave loads on the structure, and also reducing the tendency for scour; (3) the (relatively) low costs of construction, maintenance and adaptation, especially for structures in limited water depth.

Design of shore protection structures

Shore protection structures can be built on the beach or offshore in the surf zone. In the first case the structure is essentially a revetment or dike protecting the backshore, dune foot or cliff base. In the second case the structure is a breakwater. Breakwaters can protect harbors from wave loading and wave penetration or, if built parallel to the shoreline, can aim to create sheltered depositional beaches. Offshore breakwaters can also serve to protect fairways and harbors from high waves.

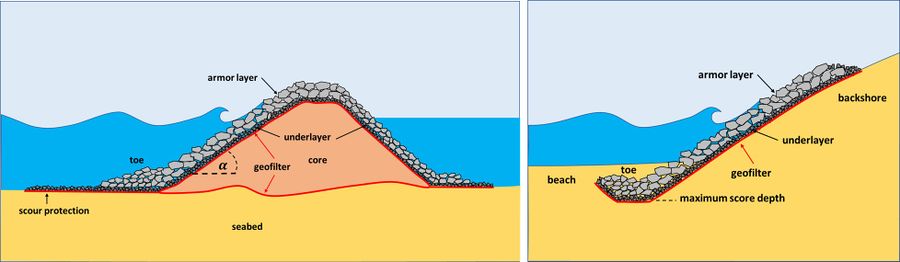

A typical design for a rubble mound breakwater is shown in Fig. 1. The basic design consists essentially of a sediment core, a geotextile, one or more granular underlayers, an armor layer of rock or concrete armor units and a toe structure.

The functions of these components are:

- The geotextile prevents erosion of the core and seabed by blocking the passage of sediment particles; however, it allows the passage of porewater. Care must be taken to ensure that the filter material is not damaged during installation. The geotextile must keep its filter function during the lifetime of the structure.

- The granular underlayer protects the geotextile against puncturing by the overlying armor elements. It softens hydraulic pressure gradients, reduces lift forces on the armor elements and provides interlocking for the armor layer above. The recommended layer thickness is at least 60 cm and the grainsize 10-20 cm[2]. General guidelines for the stability and functionality of the underlayers are given in the Rock Manual[1]

- The armor layer protects the underlayer/core against damage by wave action.

- The toe prevents sliding of the armor elements along the slope of the structure, increases the geotechnical stability against macroscopic failure and prevents undermining of the structure due to scouring.

Rubble mound breakwaters can be subdivided into non-overtopped or marginally overtopped structures, low-crested (emergent and submerged), near-bed, reef-type breakwaters and reshaping (berm) breakwaters.

It is assumed that design conditions correspond to a situation with high waves and a strong wind- and wave-driven set-up of the mean water level. In this situation waves are breaking on the armor layer of the breakwater or the rubble-mound revetment protecting the backshore. Breaking waves may exceed the crest of the offshore breakwater, but this should not happen for the backshore protection. Hydrodynamic design conditions are discussed in the section #Determination of the design conditions.]

Failure modes

Failure of a shore protection structure means: damage that result in structure performance and functionality below the minimum anticipated design[2]. Several processes can cause failure of the shore protection structure; important processes are shortly described below.

Hydraulic instability of the armor layer

Armor layer instability due to wave loading is discussed in the section #Armor layer stability.

Scour (erosion) at the toe of the construction

Toe scour due to waves and currents is discussed in the section #Toe stability and bed/scour protection. Failure of the toe construction can cause sliding down of the armor layer.

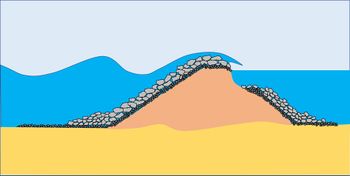

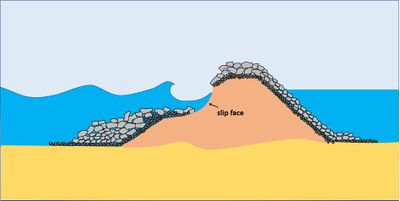

Erosion of the rear side (lee side) of a rubble mound breakwater

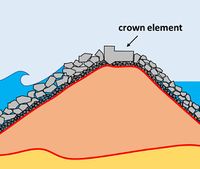

The armor layer at the rear side must be designed to withstand erosion by overtopping waves (Fig. 2). The erosive power of overtopping can be reduced by the incorporation of a crown element[1], see Fig. 3. Wave overtopping is generally expressed as an average overtopping discharge per m width, [math]q \; [m^3/s/m][/math]. The overtopping discharge of a structure depends primarily on the significant wave height [math]H_s[/math] and on the relative crest height, [math]R_c/H_s[/math], where the freeboard [math]R_c[/math] is defined as the (positive) difference between the crest level of the structure and the still water level (SWL). Formulas for estimating the overtopping discharge [math]q[/math] for different types of structures are given in the Rock Manual[1], TAW (2002)[3], Eurotop Manual (2018)[4]. The armor protection of the rear side of a breakwater should have similar size as the front side if the relative crest height [math]R_c/H_s \lt 0.3[/math]. If the relative crest height [math]R_c/H_s \gt 1[/math], hardly any wave overtopping will occur and the rear armor protection can be about three times smaller [1].

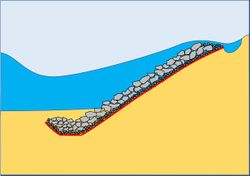

Erosion at the top of a rubble mound protection revetment

The height of the revetment should be determined such that wave run-up under design conditions does not produce significant erosion of the backshore, see Fig. 4. For wave run-up estimates see: TAW (2002)[5], Eurotop (2018) [4] and Wave run-up.

Washout of fine sediments from the core of the structure

Porewater flow due to a hydraulic pressure gradient inside the core can entrain fine sediment particles through the voids between the larger particles. In the absence of an adequate filter, fine particles are washed out of the core. The voids inside the core gradually increase until the structure collapses. The presence of a geotextile or granular filter prevents the escape of sediment particles from the core. The openings of the filter should be small enough to prevent the passage of sediment particles. However, the openings must be large enough to drain excess porewater from the core.

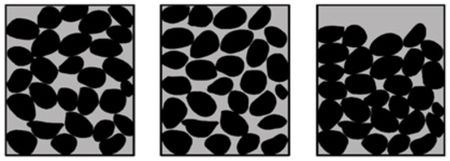

Soil liquefaction under the structure

Soil liquefaction destabilizes the seabed causing the structure to collapse, see Fig. 5. A loosely packed saturated sandy seabed can liquify under heavy load; the risk of liquefaction is greatest with well-sorted round sand particles, see Fig. 6. A seabed with a high content of clay particles (> 40%) can also liquify when loaded and subjected to strong pressure fluctuations (by wave action, seismic events) [6][7][8]. In both cases the sediment skeleton is destroyed by excess pore pressure. The susceptibility of a soil to liquefaction can be checked through Standard Penetration Tests or Cone Penetration Tests. Liquefaction risks can e.g. be reduced by replacing soft soil (expensive) or by consolidation measures. Soil consolidation can be done e.g. by vibro compaction or by preloading the soft bed with coarse sediment[9]. Monitoring of the consolidation process should ensure that a stable situation is reached.

Slip surface failure within the core

Slip surface failure can occur within the core (Fig. 7) or within the sediment body behind the revetment (slope instability)[10]. Slip surface failures develop when the effective shear stress (transmitted by contacts between sediment particles) on a slip plane exceeds a critical limit. In saturated sediment bodies, this critical limit decreases with increasing porewater pressure. Pore pressure builds up when fluctuations in the external pressure (by wave action, seismicity) cannot be levelled fast enough by porewater flow[6]. This can happen when the permeability of the sediment body is low, due to a high fraction of fine sediments. The permeability can be increased by the installation of drains. Coarse sand, gravel or quarry run are recommended as core material for rubble mound breakwaters[1]. The permeability of the geotextile must also be enough to prevent the development of excess pore pressures. A safe assumption is that the permeability of the geotextile must be at least 10 times that of the permeability of the fill material it is filtering, see Sand-filled geosystems in coastal engineering.

Instability of the foreshore

Waves and currents may generate sediment mobility. Interactions with the structure (e.g. wave reflection, wave draw-down, generation of turbulence) may result in scour of the bed or beach materials directly in front of the toe of the structure, with the potential to cause undermining. This erosion of the foreshore can then lead to slope instability and structural failure.

Armor layer stability

The stability of a coastal structure is typically assessed by using various stability criteria (based on the various failure mechanisms). Stability criteria exist for the hydraulic and geotechnical stability of the entire structure and for individual structure parts (e.g. armor, filter, core). Structural failure (of a part of the structure) occurs if the respective stability criteria are not met.

Non-overtopped or marginally overtopped structures

Here we consider non-overtopped or marginally overtopped breakwaters, i.e. breakwaters with a crest freeboard greater than zero ([math]R_c \gt 0[/math]). It is assumed that the armor layer has been put in place properly, i.e., well packed such that there are many contact points between the armor elements. The functionality of the structure will be maintained during its intended lifetime if the armor elements stay largely in place with only small adjustments of their positions. This should be the case even under the heaviest wave attack considered in the design. The most crucial design parameters are the slope of the structure and the weight of the elements. It is recommended to optimize the design by means of hydraulic model tests, in order to achieve the best functionality at the lowest costs. This is especially true for situations with a complex geometrical setting. In the following, examples of empirical rules are presented that allow a rough initial estimate of the design parameters.

The stability or the armor layer is related to the significant wave height of the incident waves [math]H_s[/math] at the toe of the structure under design conditions. It is common to define the stability number

[math]N=\Large\frac{H_s}{\Delta \, D_{n50}}\normalsize , \qquad (1)[/math]

where [math]D_{n50}[/math] is the average diameter [m] of the armor elements (the median nominal diameter, corresponding to the mass of particles for which 50% of the granular material is lighter) and [math]\Delta=(\rho_r/\rho_w)-1[/math] is the relative density of the armor elements ([math]\rho_r, \rho_w[/math] are the densities of the armor elements and seawater, respectively). For rock [math]\Delta \approx 1.65[/math] and for concrete [math]\Delta \approx 1.3-1.4[/math]. The critical maximum value of the stability number [math]N_s[/math] for which the armor layer is stable, [math]N \le N_s[/math], depends on several parameters:

- The slope [math]\alpha[/math] of the structure. The slope angle should not exceed the friction angle of about 35 degrees, i.e. [math]\cot \alpha \ge 1.5[/math] except for breakwaters with concrete armor layers which allow a steeper slope (for instance, [math]\cot \alpha=1.33[/math]); in earthquake-prone areas the critical slope angle is smaller.

- The type of filter/underlayer.

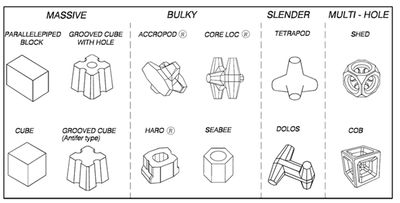

- The type of the armor elements (see Fig. 8).

- The gradation of the armor elements (thumb rule: the size of the 20% smallest elements should not be smaller than half the size of the 20% largest elements).

- The packing/porosity of the structure; the corresponding permeability parameter [math]c_p[/math] is defined as [math]c_p=[1 + (D_{core}/D_{armor})^{0.3}][/math], where [math]D_{core}, D_{armor}[/math] are the average particle sizes of the core and the armor layer, respectively.

- The acceptable damage [math]S_d[/math] during the lifetime of the structure, defined as [math]S_d=A_e/D_{n50}^2[/math], where [math]A_e[/math] is the cross-sectional area of the structure eroded by wave action. Damage is sometimes expressed as the damage number [math]N_{od}[/math], the number of displaced units within a strip of width [math]D_{n50}[/math] across the slope; the relation between [math]N_{od}[/math] and [math]S_d[/math] can be approximated by[2] [math]N_{od} \approx G(1-p)S_d[/math], where [math]G[/math] = gradation factor, depending on the armor layer gradation ([math]G \approx 1.4[/math] for stone armor) and [math]p \approx 0.5[/math]= armor layer porosity.

- The number of waves [math]n[/math] corresponding to design conditions (related to storm duration; often a maximum number [math]n[/math]=7500 is assumed).

- The wave period and steepness of the design waves. The considered wave period is [math] T_{m-1,0}[/math]= mean energy period (definition given in Statistical description of wave parameters); the wave steepness [math]s[/math] is defined as [math]s=2 \pi H_s/(g T_{m-1,0}^2)[/math].

- The mode of wave breaking. The mode of wave breaking depends on the surf similarity parameter [math]\xi=s^{-1/2} \tan \alpha[/math]. For [math]\xi \gt 1.8 [/math] waves are surging and for [math]\xi \lt 1.8[/math] waves are plunging.

- The slope of the foreshore [math]m[/math] (slopes between 1/100 and 1/30).

Several empirical formulas have been established for [math]N_s=\large\frac{H_s}{\Delta \, D_{n50}}\normalsize [/math], generally based on experiments in hydraulic models. One of the most simple and often used formulas is from Hudson (1959)[11]. It was derived from experiments with non-breaking regular waves, the water depth at the toe of the structure being much larger than the significant wave height. When written in terms of [math]H_s[/math] and [math]D_{n50}[/math] it reads

[math]N_s = \large \frac{(K_D \cot \alpha)^{1/3}}{1.27}\normalsize , \qquad (2)[/math]

where [math]\cot \alpha[/math] is the inverse average slope (width/height) of the structure. The factor [math]K_D[/math], the stability coefficient, depends on all other parameters listed above. A value of [math]K_D = 2[/math] is recommended in case of breaking waves and [math]K_D = 4[/math] in case of non-breaking waves. The formula is valid for a fixed damage level, namely 0–5 per cent of the armor stones displaced in the region of primary wave attack. Combining (1) and (2) an estimate can be derived for the required minimum weight [math]W = g \rho_r D_{n50}^3[/math] of cubic armor elements according to the formula of Hudson.

Next to the Hudson formula many stability formulae have been derived over the years for various armor and structure types and hydraulic boundary conditions. These formulae also include other relevant parameters, such as e.g. the wave period (breaker parameter) and permeability. An overview of stability formulas can be found in the Rock Manual[1] or the Coastal Engineering Manual[2]. Based on all available data Etemad-Shahidi et al. (2020) [12] derived a new optimal expression that takes into account the different parameters defined above:

[math]N_s = b \, c_p^{0.6} \, (\cot \alpha)^a \, s^{a/2} \, n^{-1/10} \, S_d^{1/6} \, (1-m) , \qquad (3)[/math]

where [math]b=3.9 , a =1/3[/math] for surging waves and [math]b=4.5, a=7/12[/math] for plunging waves.

For a structure with inverse slope [math]\cot \alpha = 1.5[/math] built on a [math]m=1/50[/math] sloping foreshore, with stone size ratio [math]D_{core}/D_{armor}=0.2[/math], subjected to [math]n=1000[/math] surging waves of design height [math]H_s[/math] and steepness [math]s=0.035[/math], the stability number according to Eq. (3) is given by [math]N_s \approx 1.3 \, S_d^{1/6}[/math]. Accepting a damage level of [math]S_d=4[/math], the safe diameter of the armor elements is [math]D_{n50} \equiv D_{armor} \approx 0.35 \, H_s[/math].

For high wave loads, requiring very large rock sizes (typically >10 ton), special concrete armor elements have been designed that provide better stability than rock armor, see Fig. 8. Experimentally determined stability numbers for randomly placed interlocking armor elements are in the range [math]N_s = 2 - 3[/math]. Interlocking concrete armor elements are susceptible to breakage[2]. Breakage of armor elements compromises the stability of the armor layer.

Emergent structures

Low-crested structures are defined here as structures overtopped by waves with their crest level roughly around still water level (SWL). These structures can be subdivided in:

- emergent structures with crest level above SWL: [math]R_c\gt 0[/math];

- submerged structures with crest level below SWL: [math]R_c\lt 0[/math].

A further distinction can be made between statically stable and dynamically stable low-crested structures, also called reef breakwaters (see below).

The distance between crest level and sea level (the so-called freeboard [math]R_c[/math]) is an important design parameter for low-crested breakwaters, as it influences the stability of the structure, as well as the relative height of the transmitted waves.

For low-crested emergent structures a part of the wave energy can pass over the breakwater. Therefore, the size or mass of the material at the front slope of such a low-crested structure might be smaller than on a non-overtopped structure. In the case of non-overtopped structures, waves mainly affect the stability of the front slope, while in the case of overtopped structures the waves do not only affect the stability of the front slope, but also the stability of crest and rear slope. Therefore, the size of the armorstone for these segments is more critical for an overtopped structure than for a non-overtopped structure.

As a rule of thumb the following formula of Kramer and Burcharth (2003)[13] can be used to obtain a first estimate of the stone size, [math]D_{n50}[/math] (relative density [math]\Delta=1.6[/math]), for emergent structures in depth-limited wave conditions ([math]H_s/h=0.6[/math]), i.e. with breaking waves on a mild-sloping foreshore ([math]m \le 0.01[/math]) [1]

[math]D_{n50} \ge 0.3 h , \qquad (4)[/math]

where [math]H_s[/math] is the significant wave height at the toe of the structure and [math]h[/math] is the water depth at the toe of the structure. Note that other values for [math]H_s/h, m, \Delta[/math] might lead to very different values for the stone size required. More detailed formulas on emergent structures are given in the Rock Manual[1].

Submerged structures

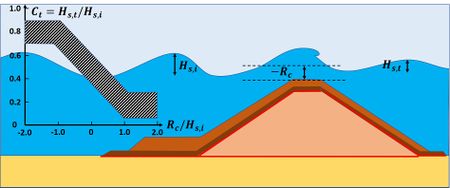

Submerged structures have their crest below water (Fig. 9), but the depth of submergence of these structures is such that wave breaking processes affect the stability. Submerged structures are overtopped by all waves and the stability increases considerably if the depth of submergence increases.

These structures transmit part of the incident waves. The wave transmission coefficient [math]C_t[/math] (ratio of transmitted wave height and incident wave height [math]C_t=H_{s, t}/H_{s, i}[/math]) depends mainly on the ratio of freeboard and incident significant wave height, the relative freeboard [math]R_c/H_{s, i}[/math]. The relationship between the transmission coefficient and the relative freeboard according to experimental data is shown in the graph of Fig. 9.

The stability criterion for submerged breakwaters is less severe (larger [math]N_s[/math]) than for emergent breakwaters, as far as the front armor layer is concerned. Therefore, smaller armor elements can be applied, with significant cost savings. However, the crest and the rear side of submerged breakwaters are relatively more vulnerable [14]. Damage at the rear side of the breakwater strongly affects the integrity of the whole structure, see Fig. 2. The size of the armor elements at the front side, the crest and the rear side should be similar if the freeboard is small or negative, [math]R_c\lt 0.3 H_s[/math] [15].

Reshaping structures (Berm and reef breakwaters)

Berm breakwaters can be differentiated into three types: Non-reshaping statically stable, Reshaped statically stable and Dynamically stable (reshaping) berm breakwaters. Here the latter are discussed. A dynamically stable (reshaping) berm breakwater is a design that allows reshaping of the breakwater profile into a stable profile, but the individual stones may still move up and down the slope. If properly designed, reshaping increases the stability of the breakwater without compromising its functionality. The berm breakwater is distinct from the classical breakwater by the addition of several stone layers at the seaward face, see Fig. 10. Reshaping means that a larger damage factor is acceptable in Eq. (3). For a fully reshaping design the damage factor [math]S_d[/math] can be as large as 20. This larger damage factor implies a larger stability number (a factor 2 is possible) and consequently less severe conditions on armor stone size and breakwater slope. The cost savings compared to the conventional design can amount to 40% [9]. Design methods for dynamically stable berm breakwaters are given by Hall and Kao (1991)[16] and Tørum et al (2003)[17].

Reef-type structures are a special type of low-crested structure that can be reshaped by wave attack. They are dynamically stable, made of homogeneous material (stones) without a filter layer or core. A reef breakwater may initially be an emerged structure and after reshaping become a submerged structure. The equilibrium crest height after reshaping and the corresponding trans- mission are the main design parameters. Design methods for different types of reshaping structures can be found in the Rock Manual[1].

Fig. 9. Submerged breakwater. The freeboard is negative. The graph shows the range of values for the wave transmission coefficient obtained from experiments [1]. |

Toe stability and bed/scour protection

The toe is a crucial component of a structure: it supports the armor layer and it prevents undermining by wave- and current-induced erosion. Different toe designs are possible; here we focus on toe structures consisting of loose elements, see Fig. 1. In some designs the toe is protected by sheet piles; these constructions will not be considered here. The seabed near the toe is susceptible to erosion. Therefore, the toe is often located below the seabed at the expected scour depth (right panel Fig. 1). If the seabed is not erodible, or if scour protection measures are applied, the toe can be situated on the seabed (left panel Fig. 1).

The toe is typically placed on a geofilter that prevents washout of fine sediment from below the toe. The geofilter is often protected by an underlayer of medium-sized stones on which larger toe elements are placed. The stability of the toe elements is ruled by considerations similar as for the armor layer. If the armorstone in the toe has the same size as the armorstone of the cover layer of the sloping front face, the toe is likely to be stable. The stability number for the toe elements is larger (up to factor 2) than for the armor elements if (under design conditions) the height of the toe (relative to the seabed) is much lower than the water depth under design conditions [1]. In that case the toe elements can be smaller than the armor elements. This has several advantages: less scour around the toe, less risk of soil liquefaction and lower costs. Stability formulas for toe structures can be found in Van Gent and Van der Werf (2014)[18] and Herrera et al. (2016)[19]. If the toe is high (height not much less than water depth) the structure is similar to a breakwater with a berm. The risk of soil liquefaction under the toe (Fig. 5) has to be investigated by laboratory tests [20]. Soil compaction, soil replacement and/or draining measures may be needed for soils with a high fraction of fine sediments.

Structures that disturb the natural flow induce a modification of the seabed morphology. Erosion dominates in the vicinity of these structures as a consequence of increased local energy dissipation of waves and currents. Erosion is greatest at the toe of reflective vertical structures. The scour depth is smaller for structures with a more gentle slope and a greater porosity. Empirical formulas for scour under the toe and in front of the toe were established by Den Bieman et al. (2019)[21], based on physical model tests with an impermeable core; in these tests ongoing erosion was observed without convergence to an equilibrium scour depth. As a rule of thumb, the maximum scour depth [math]S_m[/math] at vertical structures can be as large as the significant wave height [math]H_s[/math] under design conditions[2]. The scour depth is a decreasing function of the ratio water depth / wavelength.

Beach lowering occurs in front of structures protecting the backshore when waves collapse on the structure under storm conditions[22], see Fig. 11. Natural restoration of the beach level can occur under calm conditions in case of sufficient sand supply. In other cases, the option of artificial nourishment can be considered, see the articles Artificial nourishment and Shore nourishment.

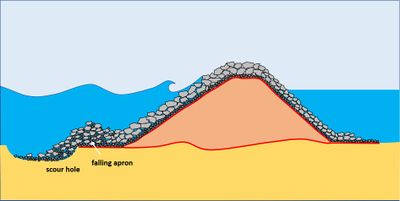

Obliquely incident waves generate a longshore current (see Shallow-water wave theory) that can strongly enhance erosion at the toe of the structure. This is particularly relevant for offshore breakwaters, where it is necessary to protect the seabed in front of the toe. This can be done with a stone cover, provided the stone size has been adjusted to the Shields criterion for critical shear stress (see Sand transport). An alternative is the so-called 'falling apron', a row of wide-graded quarry stone stacked at the edge of the toe. When a scour hole develops, the pile of stones falls into the pit and covers the bottom so that it does not erode further, see Fig. 12.

Significant currents can occur at shore-connected breakwaters and groynes (especially at breakwater heads), but also at the extremities of offshore shore-parallel breakwaters, especially for long breakwaters (length >> distance to the shore); the latter currents are driven by water set-up landward of the breakwater. Hence, particular attention is needed for scour protection of the seabed at the extremities of breakwaters. The use of a flexible mattress for protecting the seabed can be considered in case of very strong scour.

Shore protection structures such as breakwaters always require maintenance, in particular the repair of scour protection layers. An important point of attention for the design is therefore to ensure that the structure is easily accessible for maintenance.

Determination of the design conditions

Design conditions are the most destructive hydrodynamic conditions that the structure must resist without failing. More severe conditions must have a low probability of occurrence during the design lifetime. The structure may suffer some damage during design conditions, but this damage should not compromise the intended functionality of the structure. Conditions that occur more frequently should not produce damage, or the damage must be so small that the total accumulated damage during the design life of the structure remains within acceptable limits.

The ideal situation for investigating the lifetime of a structure is the availability of: (1) a record of field observations covering all hydrodynamic conditions relevant to the design, with a record length much longer than the design lifetime, and, (2) a hydraulic or numerical model capable to simulate the impact of the observed hydrodynamic conditions on the design for the entire duration of the observation record. With these tools the design can be optimized without the need to specify particular design conditions. However, this ideal situation hardly occurs in practice. A possible solution consists in constructing a dataset as intended under (1) from historical meteorological records, using a numerical hydrodynamic model.

The modelling step (2) is generally very demanding in time and costs. In practice, structures are tested in hydraulic and/or numerical simulation models for a selected set of hydrodynamic design conditions such as the Serviceability Limit State (SLS) and Ultimate Limit State (ULS). The SLS describes the performance of the structure under normal conditions. The ULS represents extreme events with a low probability of occurrence during the design lifetime (based on acceptable risk agreed between contractor and client). The extreme hydrodynamic conditions are derived from a statistical analysis of available data. The final verification of the design is usually performed using a physical model. The most important design parameters are:

- The incident significant wave height [math]H_s[/math] at the toe of the structure (the 2% highest wave height [math]H_{2\%}[/math] is sometimes preferred);

- The wave period [math]T[/math];

- The wave incidence direction;

- The extreme water levels;

- The storm duration.

For offshore breakwaters in deep water, the extreme significant wave height and storm duration are usually the most critical design parameters. If available historical records of these parameters are too short for extracting directly the design values, they can be obtained from extreme value analysis. For the significant wave height this can be done, for example, by fitting significant wave heights above a certain threshold level to a Weibull distribution. The scour depth at the toe of the structure depends in general mainly on wave height and wave direction; frequent periods of energetic waves can be more relevant than exceptional extreme conditions. For estimating the scour depth, knowledge from field observations is required of the correlation between wave height and wave direction during such periods.

For breakwaters and revetments in shallow water the wave height is limited by depth-induced breaking. Deep-water wave data therefore have to be transformed to shallow water conditions (as explained in Shallow-water wave theory and Statistical description of wave parameters). The extreme water level is another important design parameter for structures in shallow water and on the beach: it determines the water depth above the toe of the structure and it influences the height of the waves breaking on the structure, the wave run-up and possible overtopping of the revetment. Extreme water levels are related to storm events and therefore correlate with extreme wave heights, but they are also influenced by the astronomical tide that is hardly correlated with wave height. The most critical combination of (extreme) water level and (extreme) wave height that may occur can be found by modelling the local hydrodynamic conditions with input from historical meteorological records and by constructing in this way a dataset of sufficient length. Other methods are described in Hawkes et al. (2002)[23] and in the Rock Manual[1].

Further reading

- Schiereck, G.J. 1993. Introduction to bed, bank, shore protection. TU Delft, Department Hydraulic Engineering.

- Pilarczyk, K. (editor) 1998. Dikes and Revetments. A.A. Balkema (publisher)

References

- ↑ 1.00 1.01 1.02 1.03 1.04 1.05 1.06 1.07 1.08 1.09 1.10 1.11 1.12 CIRIA/CUR/CETMEF 2007. The Rock Manual. The use of rock in hydraulic engineering (2nd ed.). C683. London: CIRIA

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 USACE, 2012. Coastal engineering manual. Report No 110-2-1100. Washington DC: US Army Corps of Engineers https://www.publications.usace.army.mil/USACE-Publications/Engineer-Manuals/u43544q/636F617374616C20656E67696E656572696E67206D616E75616C/

- ↑ TAW. 2002. Technical Report Wave Run-up and Wave Overtopping at Dikes. Publication Technical Advisory Committee on Flood Defence, Delft

- ↑ 4.0 4.1 Van der Meer, J.W., Allsop, N.W.H., Bruce, T., De Rouck, J., Kortenhaus, A., Pullen, T., Schüttrumpf, H., Troch, P. and Zanuttigh, B. 2018. Manual on wave overtopping of sea defences and related structures, 2nd ed. http://www.overtopping-manual.com/ Cite error: Invalid

<ref>tag; name "EU" defined multiple times with different content - ↑ TAW. 2002. Technical Report Wave Run-up and Wave Overtopping at Dikes. Publication Technical Advisory Committee on Flood Defence, Delft

- ↑ 6.0 6.1 Sumer, B.M. and Fredsøe, J. 2002. The Mechanics of Scour in the Marine Environment. World Scientific, Advanced Series on Ocean Engineering, Volume 17

- ↑ de Groot, M. B., Bolton, M. D., Foray, P., Meijers, P., Palmer, A. C., Sandven, R., Sawicki, A. and Teh, T. C. 2006. Physics of Liquefaction Phenomena around Marine Structures. Waterway, Port, Coastal, Ocean Eng. 132: 227-243

- ↑ Chávez, V., Mendoza, E., Silva, R., Silva, A. and Losada, M.A. 2017. An experimental method to verify the failure of coastal structures by wave induced liquefaction of clayey soils. Coastal Engineering 123: 1–10

- ↑ 9.0 9.1 Van der Meer, J. and Sigurdarson, S. 2017. Design and construction of berm breakwaters. Advanced Series on Ocean Engineering vol. 40, World Scientific Publ. Co., Singapore

- ↑ USACE 2003. Slope stability. Engineering and Design. US Army Corps of Engineers, Manual No. 1110-2-1902

- ↑ Hudson, R.Y. 1959. Laboratory investigation of rubble-mound breakwaters. J. Waterw. Harb. Div. ASCE 85: 93–121

- ↑ Etemad-Shahidi, A., Bali, M. and van Gent, M.R.A. 2020. On the stability of rock armored rubble mound structures. Coastal Engineering 159, 103655

- ↑ Kramer, M. and Burcharth, H.F. 2003. Stability of low-crested breakwaters in shallow water short crested waves. Proc. Coastal Structures 2003 Conference, Portland, Oregon, USA

- ↑ Burger, G. 1995. Stability of low-crested breakwaters: stability of front, crest and rear. Influence of shape and gradation. Report H1878/H2415, WL|Delft Hydraulics

- ↑ Van Rijn, L.C. 2016. Stability design of coastal structures. www.leovanrijn-sediment.com

- ↑ Hall, K. and Kao, S. 1991. A study of the stability of dynamically stable breakwaters. Can. J. Civ. Engineering 18: 916-925

- ↑ T/orum, A., Kuhnen, F. and Menze, A. 2003. On berm breakwaters. Stability, scour, overtopping. Coastal Engineering 49: 209-238

- ↑ Van Gent, M.R.A. and Van der Werf, I.M. 2014. Rock toe stability of rubble mound breakwaters. Coastal Engineering 83: 166–176

- ↑ Herrera, M.P., J. Molines and Medina J.R. 2016. Hydraulic stability of nominal and sacrificial toe berms for mound breakwaters on steep sea bottoms. Coastal Engineering 114: 361-368

- ↑ Bradbury, A., Rogers, J. and Thomas, D. 2012. Toe structures management manual. Environment Agency https://www.gov.uk/government/publications/toe-structures-management-manual

- ↑ Den Bieman, J.P., Van Gent, M.R.A. and Hoonhout, B.M. 2019. Physical model of scour at the toe of rock armored structures. Coastal Engineering 154, 103572

- ↑ Sutherland, J., Brampton, A.H., Obhrai, C., Dunn, S. and Whitehouse, R.J.S. 2007. Understanding the lowering of beaches in front of coastal defence structures, stage 2. Joint Defra/Environment Agency Flood and Coastal Erosion Risk Management R&D Programme, R&D Technical Report FD1927/TR. London: Defra

- ↑ Hawkes, P.J., Gouldby, B.P., Tawn, J.A. and Owen, W.O. 2002. The joint probability of waves and water levels in coastal engineering design. Journal of Hydraulic Research 40: 241-251 https://www.researchgate.net/publication/245328536

Please note that others may also have edited the contents of this article.

|