Difference between revisions of "Pump sampling in unidirectional and oscillatory flow"

(→Automatic pump samplers) |

m (Pump sampling in unidirectal and oscillatory flow moved to Pump sampling in unidirectial and oscillatory flow: spelling correction) |

(No difference)

| |

Revision as of 16:56, 26 November 2007

This article is a summary of sub-section 5.6.3.1 and 5.6.3.2 of the Manual Sediment Transport Measurements in Rivers, Estuaries and Coastal Seas[1]. This article describes the general aspects of pump sampling in oscillatory (coastal) flow and unidirectional (river) flow.

Contents

Pump sampling in oscillatory flow

Pump sampling is an attractive method for concentration measurements in coastal conditions because a relatively long sampling period can be used which is of essential importance to obtain a reliable time-averaged value. The sampling period should be rather long (15 min) in irregular wave conditions (at least 100 waves). A problem of sampling in conditions with irregular waves is that the magnitude and direction of the fluid velocity is changing continuously. This complicates the principle of isokinetic sampling in the flow direction. A workable alternative may be the method of normal (or transverse) sampling, which means that the intake nozzle of the sampler is situated normal to the plane of fluid velocity. Bosman et al (1987)[2] studied the sampling error related to the orientation of the intake nozzle, because they were interested in pump sampling under wave conditions. They found that a transverse pumping direction yields good results. The intake nozzle is directed downward or normal to the plane of orbital motion. Figure 1 shows the ratio c/co as a function of the ratio u/uo and the nozzle orientation for 170 um-sediment (c = measured concentration, co = original concentration, u = intake velocity, uo = local ambient velocity). For transverse orientation (90°) and ratio of u/uo> 2, the c/co-ratio is about 0.7 to 0.8 which means a systematic error of 20% to 30% in the measured concentration. Similar results were obtained for 220 um, 280 um, 360 um and 450 um-sediment. This systematic error can be corrected for.

Peristaltic pumps have proven to be very efficient in coastal conditions.

Pump-sampling in unidirectional flow

To obtain a reliable average sediment concentration, the sampling or measuring period should be rather large (about 300 seconds). Furthermore, the collection of a large sediment sample for size-determination by sieving or settling tests requires the sampling of a relatively large water volume (about 25 to 50 litres). Both requirements can be satisfied by collecting water samples by means of a pump in combination with an in-situ separation of water and sediment particles. Usually a pump sampler consists of a submergible carrier (with intake nozzle, current meter and echo-sounder, see Figure 1 and 3), a deck-mounted pump and a flexible hose connecting the intake nozzle and the pump. The hose diameter should be as small as possible to reduce the stream drag on the hose. Using a hose diameter (bore) in the range of 0.003 to 0.016 m, the pump discharge will be in the range of 1 to 30 litres per minute. In case a deck-mounted pump is used the maximum suction lift will be about 7 m. Assuming a static lift (= height of pump above water level) of about 2 m, the suction lift available for operation of the pump will be about 5 m resulting in a maximum hose length of about 50 m (Van Rijn, 1979[3]). In extreme deep waters an underwater pump must be used. Operation of a pump sampler is limited to flow conditions with velocities smaller than 2 m/s because of excessive stream drag on the pumphose and carrier.

Type of pump

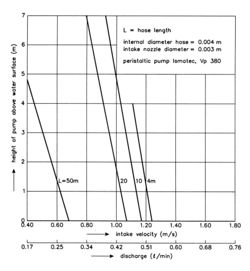

Peristaltic pumps or propeller type pumps can be used. Peristaltic pumps (24 volt/220 volt) (see http://www.globalw.com www.globalw.com) have proven to be very efficient for pump sampling in river and coastal conditions. The discharge is relatively small (1 1/min) yielding a relatively small water-sediment sampling which can be handled easily. The hose diameter is extremely small (0.006 m), which reduces the fluid dragforces on the hose. The pump direction can be easily changed to remove small objects (shell fragments, organic materials, etc.) blocking the intake nozzle. The intake velocity in relation to the static suction lift (= height of pump above water surface) and the hose length is given in Fig. 2. Propeller type pumps (see Website about common garden pumps) produce a relatively large discharge (10 1/min) resulting in the handling of a large water-sediment volume. The hose diameter is in the range of 0.01 to 0.016 m.

Intake velocity and accuracy

Ideally, the intake velocity of the water-sediment sample should be equal to the local flow velocity. In conditions with varying velocities this would mean a continuous adjustment of the intake velocity. For practical reasons it is preferable to operate the pump system as much as possible with a fixed discharge and hence a fixed intake velocity. This can be done by using a fixed intake velocity for each class of flow velocities.Using this method, the hydraulic coefficient will be in the range of 0.8 to 2.0 during pump sampling, resulting in a maximum error in the concentration of about 20%, which is quite acceptable for concentration measurements. For reasons of effective sampling, the flow velocity in the hose must be larger than 1.0 m/s (Van Rijn, 1979 [3]).

Determination of hose dimensions and carrier type

The maximum hose length is about 50 m using a deck-mounted pump, which enables sampling in channels with flow depths upto 25 m. In shallow water the hose dimensions and also the carrier dimensions can be reduced substantially. Figure 2 can be used to select the required hose dimensions (bore diameter and length) for a propeller type pump and carrier type, given specific flow conditions.

The carrier should satisfy the following specifications:

- streamlined body,

- small cross-section area,

- low centre of gravity,

- suspension cable attached to swivel,

- large tail fin,

- supporting pins (at bottom side) and hand grips for transportation,

- adjustable ballast weight (lead).

Determination of sampling position

To determine the actual position of the intake nozzle above the bed, an echo-sounder attached to the carrier should be used. Usually it is desirable to have a sampling position close to the bed. This can be achieved by placing the carrier on the bed. In that case the position of the intake nozzle is equal to the distance between the nozzle and the underside of the carrier (see Figure 2). When measurements at a few centimetres above the bed are necessary, special equipment should be used which allows the vertical adjustment of the intake nozzle over a certain range (remote controlled) or additional intake nozzles should be attached to the carrier.

Handling of water volume after sampling

When a propeller type pump is used, a large water-sediment volume is obtained. The handling of a large water-sediment volume requires the in-situ separation of water and sediment particles. A practical solution can be obtained by using the filtration method or the sedimentation method. In case the collection of a large quantity of sediment particles for size analysis is not of importance, it is advisable to take a relatively small, but representative sample of the total water sample to determine the sediment concentration. This latter method is discussed as the pump-bottle method. When a peristaltic pump is used, a relatively small amount of water is obtained (2 liters in 5 minutes) . This small sample can be stored in a bottle and returned to the laboratory for analysis.

Automatic pump samplers

Site location, flow conditions, frequency of collection and operational costs sometimes make collection of sediment data by manual methods impractical. For these reasons automatic pumping type samplers have been developed (for more information on FTS, see www.ftsinc.com www.ismatec.com).

Such a sampler consists of:

- intake nozzle and tubing system,

- pump to draw water-sediment samples from the flow (flushing of tubing system after sampling is necessary),

- sample container unit to hold sample bottles in position for filling,

- sample distribution system to divert a pumped sample to the correct bottle,

- activation system that starts and stops the sampling cycle.

See also

Summaries of the manual

- Manual Sediment Transport Measurements in Rivers, Estuaries and Coastal Seas

- Chapter 1: Introduction, problems and approaches in sediment transport measurements

- Chapter 2: Definitions, processes and models in morphology

- Chapter 3: Principles, statistics and errors of measuring sediment transport

- Chapter 4: Computation of sediment transport and presentation of results

- Chapter 5: Measuring instruments for sediment transport

- Chapter 6: Measuring instruments for particle size and fall velocity

- Chapter 7: Measuring instruments for bed material sampling

- Chapter 8: Laboratory and in situ analysis of samples

- Chapter 9: In situ measurement of wet bulk density

- Chapter 10: Instruments for bed level detection

- Chapter 11: Argus video

- Chapter 12: Measuring instruments for fluid velocity, pressure and wave height

External links

- Sub-section 5.6.3.1 of the manual (unidirectional flow)

- Sub-section 5.6.3.2 of the manual (oscillatory flow)

- www.ftsinc.com (http://www.ftsinc.com)

- www.ismatec.com (http://www.ismatec.com)

Further reading

Crickmore, M.J. and Aked, R.F.( 1975). Pump Sampler for Measuring Sand Transport in Tidal Waters Conference on Instrumentating Oceanography, I.E.R.E., Proc. No. Bangor, England.

Antsyferov, S.M., Basinski, T. and Pykhov, N.V. (1983). Measurements of Coastal Suspended Sediment Concentrations. Coastal Engineering, 7, Elsevier Publishers, Amsterdam, The Netherlands.

References

- ↑ Rijn, L. C. van (1986). Manual sediment transport measurements. Delft, The Netherlands: Delft Hydraulics Laboratory

- ↑ Bosman, J.J., Velden, E.T.J.M., van der and Hulsbergen, C.H. (1987) Sediment Concentration Measurement by Transverse Suction. Coastal Engineering, Vol. 11, p. 353-370.

- ↑ 3.0 3.1 Rijn, L.C. van (1979). Pump Filter Sampler. Delft Hydraulics Laboratory, Report S404, The Netherlands.

Please note that others may also have edited the contents of this article.

|

Please note that others may also have edited the contents of this article.

|