Bottle and trap samplers

This article is a summary of sub-sections 5.6.2.1, 5.6.2.2 and 5.6.2.3 of the Manual Sediment Transport Measurements in Rivers, Estuaries and Coastal Seas [1]. This article describes general aspects of bottle and trap samplers. These samplers can be used to determine the silt and/or sand concentration at a specific point in the flow. The article also describes the sampling errors that occur when using bottle and trap samplers.

Contents

Bottle-sampler

Introduction

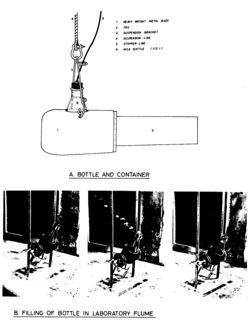

The method is based on the filling of a bottle to determine the silt and/or sand concentration at a specific point in the flow. Usually, the bottle is placed vertically in a container (Figure 1) and lowered to the sampling point, where the bottle is opened (mechanical or electrical). A cork ball should be present to close the bottle after filling. The exact filling time is unknown but may vary from about 20 to 400 sec, depending on the bottle orientation, flow velocity and sampling height as shown in Figure 2A (Delft Hydraulics, 1980[2]). Rapid profile measurement can be achieved by using a rack with 5 bottles (or more), which are opened at prefixed depths. In the case of a large amount of samples the laboratory analysis can be reduced considerably by using an optical method to determine the silt concentration (after separation of sand particles using the 50 um-sieve). About 10% of the samples are filtered to obtain a calibration curve. However, this method may introduce additional errors due to scatter of the calibration curve. Another alternative method is the use of ultra-centrifuge tubes to separate the silt particles.

The silt and sand concentrations are determined as:

[math]c\,=G\,/V\,[/math]

in which: G= dry mass of sediment (mg), V = volume of water sample (l).

Calibration curve

Measurements in a laboratory flume (Delft Hydraulics, 1980[2]) have shown that the efficiency of a bottle in collecting the sand particles (> 50 um) is strongly dependent on the orientation of the bottle opening to the main flow direction. Figure 2B shows the bottle efficiency as a function of the angle (alpha) with the flow direction. The optimal angle is about 35°. For alpha < 35° the measured concentration is too small, while for alpha > 35° the measured concentration is too large. Using a bottle in a vertical position, the inaccuracy of the measured sand concentration may be as large as 50%. In field conditions the inaccuracy of the measured sand concentration may even be larger when the filling time is small compared with the characteristic time scale of the fluctuating concentrations. The inaccuracy of the measured silt concentrations may be about 10%.

Trap samplers

Instantaneous trap sampler

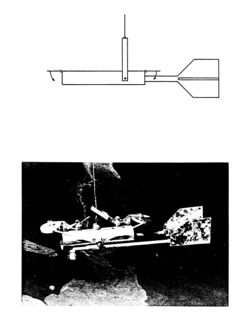

The instantaneous trap sampler consists of a horizontal cylinder equipped with end valves which can be closed suddenly (by a messenger system) to trap a sample instantaneously, as shown in Figure 3. The water is allowed to flow through the horizontal cylinder while the sampler is lowered to the desired point. As the trap sampler yields an instantaneously measured concentration, many samples are necessary to obtain a statistically reliable average value. The silt and sand concentrations can be determined with the same formula as for bottle samplers (see former section).

Time-integrating trap sampler

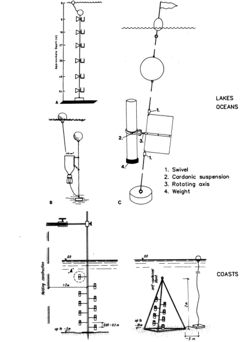

The trap sampler used in lakes and oceans consists of a cylinder-shaped or funnel-shaped box with a closed bottom and placed vertically in the water column, see Figure 4. These traps are used to determine: the deposition rate at a certain elevation, and the sediment concentration at a certain elevation. In still water the trapping efficiency is unity. In flowing water the trapping efficiency depends on many factors: turbulence generated inside trap, trap geometry, concentration and fall velocity of particles. Cylinders were found to give the most accurate results. The trapping efficiency was found to be 0.8 to 1.2 for mud suspensions in current velocities of 0.05 to 0.1 m/s (Bloesch and Burns, 1980[3]; Gardner, 1980[4] [5]). The ratio of the height and diameter of the trap should be in the range of 3 to 5. Funnel-shaped traps were found to give an underestimation of the deposition rate in flowing water. Traps with a small mouth and a wide body (bottle) were found to give a large overestimation of the deposition rate. Antsyferov et al (1990)[6]. used tripods and poles equipped with traps to measure the sediment concentrations in coastal conditions (surfzone). The traps consisted of cylinder-shaped boxes (height = 0.1 m, diameter = 0.075 m) with six openings of 7.5 mm at the upper part of the boxes, see Fig. 2. The traps were set into operation (by divers) by aligning corresponding openings in the trap body and in the cover.

The concentration of size fraction i at height z is given as:

[math]c_i(z)= M_i/(k_e F \Delta\,T U_t)[/math]

in which:

- [math]M_i\,[/math]= sediment mass of fraction i in trap

- [math]F\,[/math] = area of intake openings projected normal to wave direction,

- [math]\Delta\,T[/math]= sampling period,

- [math]U_t\,[/math] = time-averaged value of the absolute horizontal orbital velocity at height z,

- [math]K_e\,[/math] = trapping coefficient.

The k-value was obtained from field and laboratory calibrations. Concentrations were measured by means of a pump sampler close to the sand traps. Velocity measurements were also performed close to the trap (0.5 to 0.8 m/s). Antsyferov et al (1990)[6] found: ke = 0.26 for field conditions, and ke = 0.21 for laboratory conditions. The k-values are only valid for steady wave conditions (during period DT). In storm conditions with growth, stabilization and decay of the waves, the Ke-value is different. It was found that 70% of the sediment mass was trapped during the growth and decay phase of the waves (inside breaker zone).

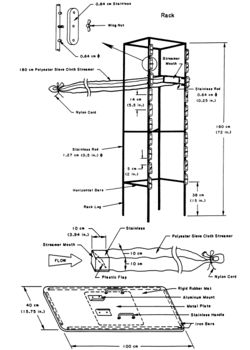

Katori (1983)[7] and Kraus (1987)[8] used portable streamer traps to measure transport rates in the surf zone, see Figure 5. The traps consist of long rectangular bags of polyester sieve cloth material (100 um) vertically mounted on a stainless steel rack (Kraus, 1987[8]). An operator standing downcurrent attends the trap during a sampling interval of 10 min. The use of these traps is restricted to shallow water (1 m) with wave heights less than about 0.5 m. Katori (1983)[7] used a similar trap to measure cross-shore transport at the bed. The trap was mounted on a rubber mat resting on the bed (to prevent scour), see Figure 5.

Sampling errors of bottle and trap samplers

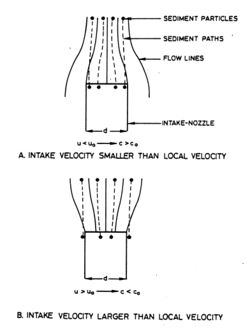

The basic principle of all mechanical bottle and trap samplers is the collection of a water-sediment sample to determine the local sediment concentration, transport and/or particle size by physical laboratory analysis. Optimal sampling of a water-sediment volume by means of a mechanical instrument requires an intake velocity equal to the local flow velocity (iso-kinetic sampling) or a hydraulic coefficient, defined as the ratio of the intake velocity and local flow velocity, equal to unity (hc=1).

Differences between the intake velocity and local flow velocity result in sampling errors. Sampling at a lower velocity than that of the ambient flow would result in a higher sediment concentration than present in the flow due to diverging flow lines, which cannot be followed by the sediment particles, being of higher density than the water particles (Figure 6A). Conversely, sampling at a higher velocity than that of the ambient flow would result in a lower sediment concentration (Figure 6B). The magnitude of error due to incorrect intake velocities in suspensions of various concentrations has been determined experimentally by Nelson and Benedict (1950)[9], whose results are shown in Figure 7. The results show a decreasing effect with a decreasing particle size. It is also clear that a hydraulic coefficient smaller than 1 results in a relatively large error. Further Nelson and Benedict[9] found no significant change of the sampling error in relation to the flow velocity (range 0.9 to 1.5 m/s), the size of the intake nozzle (range of 4 to 7 mm), the angle between flow direction and nozzle axis (range 0° to 20°), for a hydraulic coefficient in the range of 0.5 to 2 in all tests.

Crickmore and Aked (1975)[10] report that no systematic trends can be distinguished for a hydraulic coefficient in the range 0.5 to 4 and particle sizes from 60 pm to 250 um. The maximum experimental error found was about 10%.

Laboratory tests using an intake nozzle normal to the flow direction show errors of about 15% for particle sizes of 150 um and 450 um, while for 60 um-sediment no errors were found (Nelson and Benedict, 1950[9]). Hulsbergen (1981)[11] using an intake nozzle normal to the flow direction reports an error of about -15% (actual concentration larger than measured concentration) for 60 um-sand, of about -25% for 110 um and 270 um-sand and of about -33% for 500 um-sand. In all tests the hydraulic coefficient was in the range 1 to 4. Crickmore and Aked (1975)[10] found a maximum error of 20% for a misalignment of 180° using a hydraulic coefficient larger than 1.

Bottle and Trap samplers are usable in steady flow conditions (rivers), but not in time-dependent flow conditions (estuaria and coasts).

See also

Summaries of the manual

- Manual Sediment Transport Measurements in Rivers, Estuaries and Coastal Seas

- Chapter 1: Introduction, problems and approaches in sediment transport measurements

- Chapter 2: Definitions, processes and models in morphology

- Chapter 3: Principles, statistics and errors of measuring sediment transport

- Chapter 4: Computation of sediment transport and presentation of results

- Chapter 5: Measuring instruments for sediment transport

- Chapter 6: Measuring instruments for particle size and fall velocity

- Chapter 7: Measuring instruments for bed material sampling

- Chapter 8: Laboratory and in situ analysis of samples

- Chapter 9: In situ measurement of wet bulk density

- Chapter 10: Instruments for bed level detection

- Chapter 11: Argus video

- Chapter 12: Measuring instruments for fluid velocity, pressure and wave height

Other internal links

Examples of bottle and trap samplers:

- USP-61 suspended load sampler

- Delft Bottle suspended load sampler

- USP-61 suspended load sampler

- Collabsible-Bag depth integrating sampler

Further reading

- Hayes, F.Ch. (1978)Guidance for Hydrographic and Hydrometric Surveys. Delft Hydraulics Laboratory, Publication No. 200, The Netherlands.

- Van Rijn, L.C. van (1979) Pump Filter Sampler. Delft Hydraulics Laboratory, Research Report S404, The Netherlands.

References

- ↑ Rijn, L. C. van (1986). Manual sediment transport measurements. Delft, The Netherlands: Delft Hydraulics Laboratory

- ↑ 2.0 2.1 Delft Hydraulics (1980) Investigation Vlissingen Bottle (in Dutch). M1710. Delft, The Netherlands.

- ↑ Bloesch, J. and Burns, N.M.(1980) A Critical Review of Sedimentation Trap Technique. Schweiz. Z. Hydrol. 42, No. 1, p. 15-55.

- ↑ Gardner, W.D.(1980) Sediment Trap Dynamics and Calibration. Journal of Marine Research, Vol. 38, No. 1, p. 16-39.

- ↑ Gardner, W.D.(1980) Field Assessment of Sediment Traps. Journal of Marine Research, Vol. 38, No. 1, p. 41-52.

- ↑ 6.0 6.1 Antsyferov, S.M., Belberov, Z.K. and Massel, S.(1990)Dynamical Processes in Coastal Regions. Publishing House, Bulgarian Academy of Sciences

- ↑ 7.0 7.1 Katori, S.(1983)Measurement of Sediment Transport by Streamer Trap (in Japanese). Report No. 17, TR-82-1, Nearshore Environment Research Center, Japan.

- ↑ 8.0 8.1 Kraus, N.C. (1987) Application of Portable Traps for Obtaining Point Measurements of Sediment Transport Rates in the Surf Zones. Journal of Coastal Research, Vol. 3, No. 2.

- ↑ 9.0 9.1 9.2 Nelson, M.E.and Benedict, P.C.(1950) Measurement and Analysis of Suspended Sediment Loads in Streams. A.S.C.E.-Proceedings, Volume 76, U.S.A.

- ↑ 10.0 10.1 Crickmore, M.J. and Aked, R.F.(1975) Pump Sampler for Measuring Sand Transport in Tidal Waters. Conference on Instrumentating Oceanography, I.E.R.E., Conference Proceeding No. 2, Bangor, England.

- ↑ Hulsbergen, C.H., (1981) Determination of Sand Concentration by Pump Sampling normal to the flow. Delft Hydraulics, M1267, Delft, The Netherlands.

Please note that others may also have edited the contents of this article.

|

Please note that others may also have edited the contents of this article.

|